« Services

Materials Testing

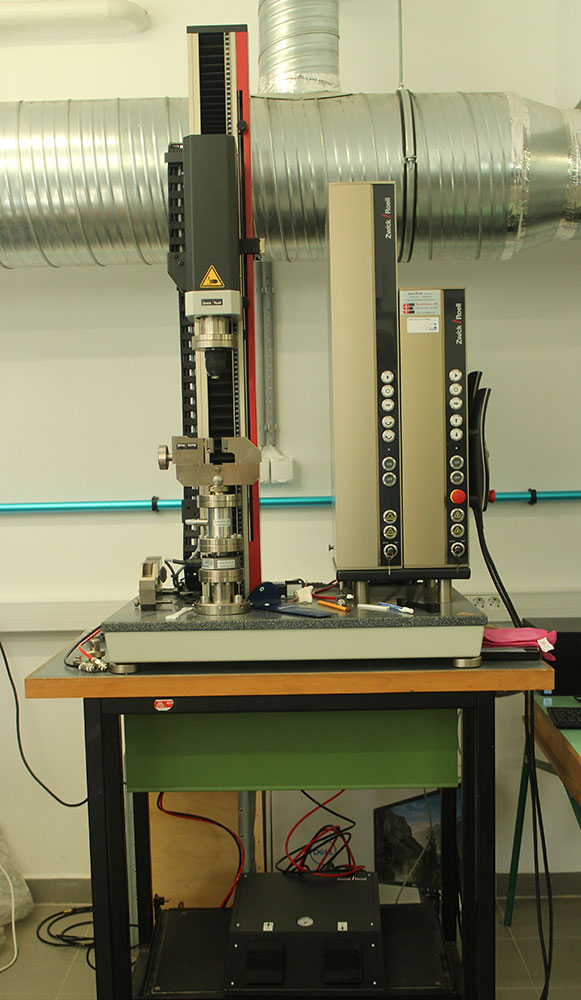

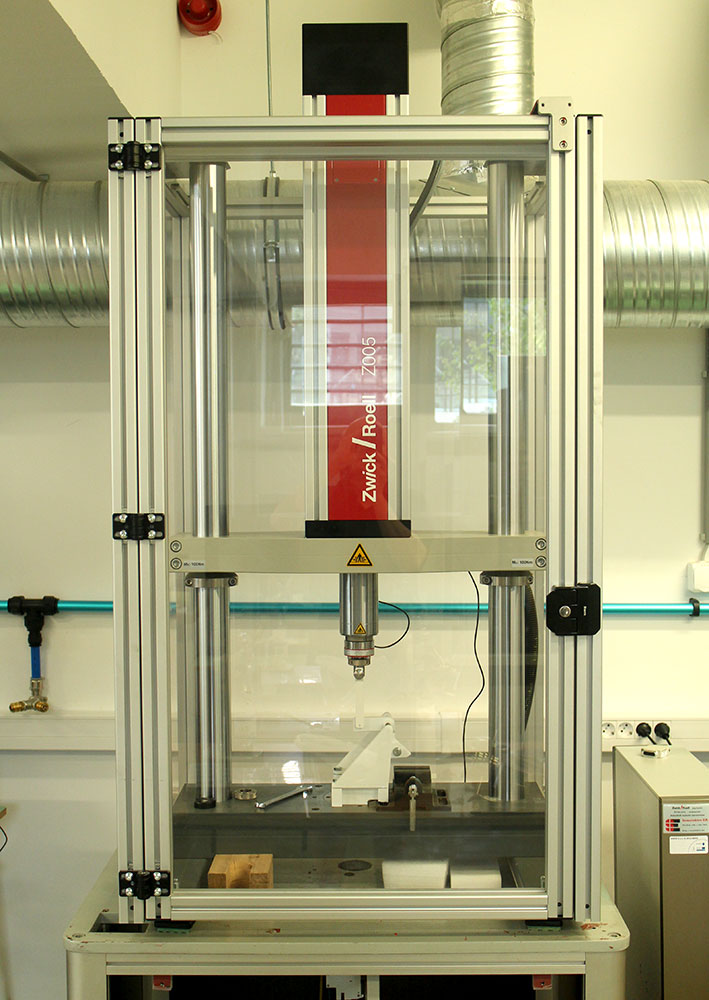

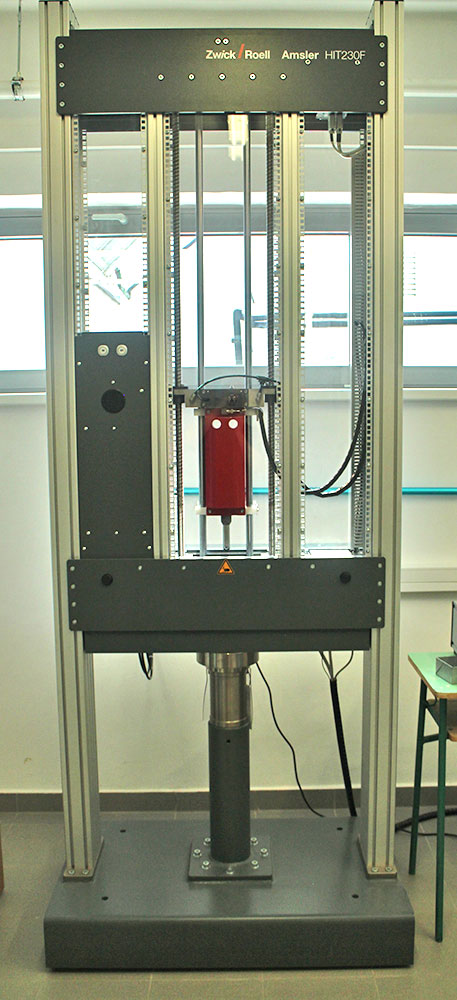

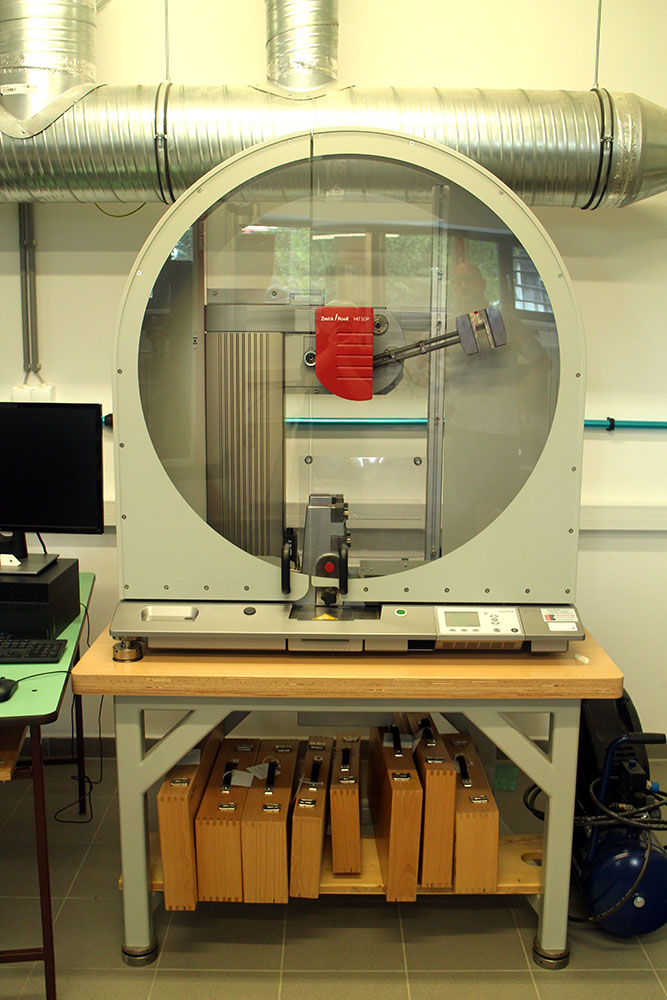

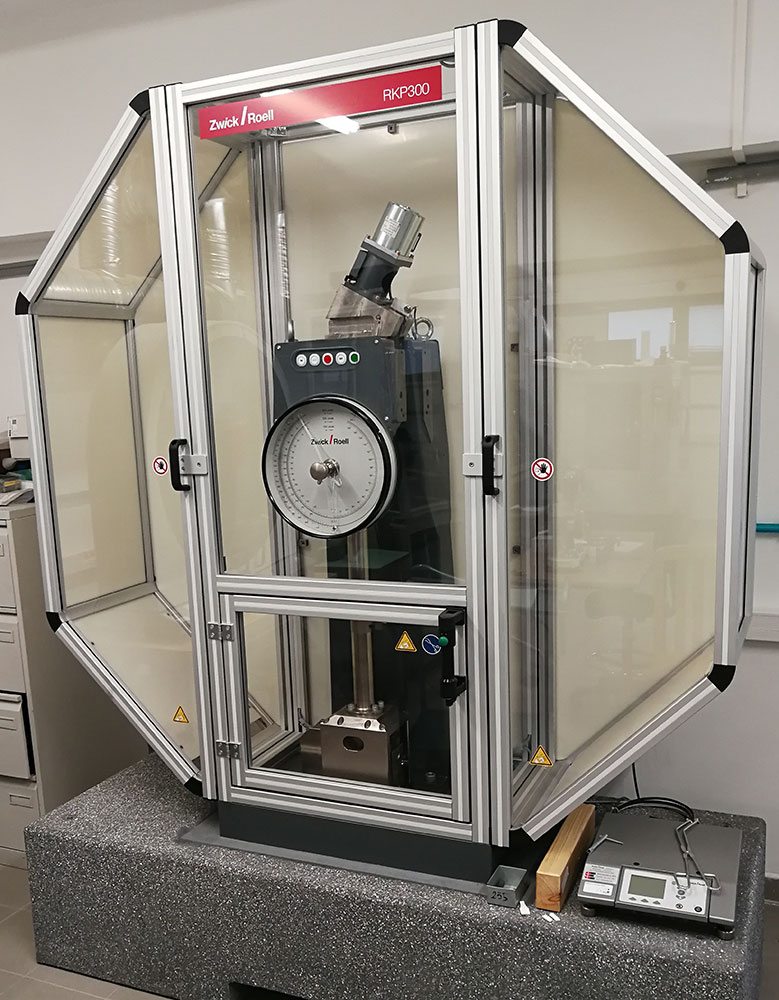

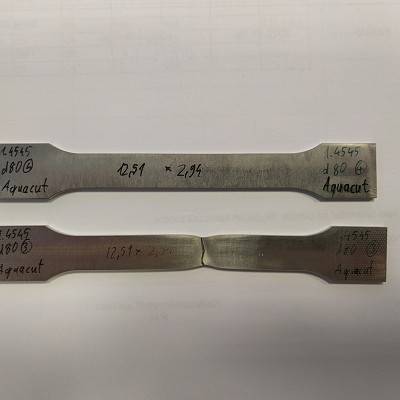

The equipment that makes up the machine park of the UP-3D Centre Materials Testing Laboratory consists of ZwickRoell destructive materials testing machines, purchased in 2019, which can be used to perform static and dynamic testing. Our activities are multifaceted; besides serving the market by primarily fulfilling industrial orders, the lab is also used for research and development projects within UP and its consortiums, as well as for educational purposes, such as demonstration classes for future engineers.