« News

Medicine and 3D Print Technology: Is the era of “Artisan” Medication Now Among Us?

2019-01-24

...

2019-01-24

...

The researchers of the Faculty of Pharmacy and the University’s 3D Print Technology Center are developing new, highly personalized and significantly more efficient medicines when compared to the traditional forms of oral medication, such as capsules, lozenges, gels, tablets and pills. In the beginning , the ‘superpills’ will first be administered throughout participating Clinics, however, in the future one might to be administered personalized medicines in the pharmacies.

The era in which a patient must commit to swallowing several handful of capsules, tablets and pills including doctors who are faced with a lengthy list of different active substance combinations in order to find the most effective therapies may very well be coming to an end, thanks in large part to emerging, cutting edge 3D printing technologies. Of course, the pharmacy industry’s revolutionary transformation must overcome many scientific and financial hurdles, yet the solution developed among the researchers of the University of Pécs may lead to significant changes among the clinics, and, in the short term.

“The traditional extrusion technology can achieve significant advances when considering the manufacturing sector regarding today’s medicine, however, there are serious technological limitations. The most significant among these limitations are the numbers of different active substances found in one capsule, tablet or pill. The traditional technology only allows the combination of three different substances in a pill, since the mixed agents tend to react to one another,” explains Dr. Szilárd Pál, the Director of the Institute of Pharmaceutical Technology and Biopharmacy. However, the Institute’s two young researchers, Dr. Márton Kopcsányi and Dr. Gyula Farkas have recently developed a contemporary method which allows a potential combination of up to ten different active substances within one pill!

The secret of the method lies in the intricate design of the capsule, tablet or pill. The interior of today’s 3D manufactured pill resembles a variety of honeycombs, regarding the structure, of which, is comprised of unique, separate compartments representing each of the corresponding forms of medication. The genius is in how these compartments serve in isolating the variety of medications and therefore, no longer risk inadvertently and prematurely combining and reacting with one another. Ultimately, the result implies one 3D printed pill replaces five to six conventional pills.

Notably, the practicality glistens, since, one only has to swallow a single pill instead of a handful, is thus far, just one of the advantages these ‘artisan’ pills offer humankind. “The structure of the pills allows us not only to combine different substances, we can now effectively control the speed of their absorption. This means we can manufacture personalized medicine in support of clinical patients,” reveals Dr. Márton Kopcsányi, one of the key researchers.

The clinical use is a priority among researchers, since today’s expense and speed associated with 3D medicine manufacturing can no longer compete on equal ground with the traditional mass manufacturing, in the terms of cost and speed, at least for now.

Admittedly, there is an immense and ever growing need for personalized medicines. “We constantly discuss among our clinical colleagues this very issue, and there is a consensus in which personalized medicine can make treating illness easier, both regarding the patients’ quality of life and the laborious research required when considering the selection and administration of new medicine. And this may become a reality very soon, at least in regards to the local clinics,” states Dr. Szilárd Pál.

The propagation of 3D printing and the diminishing costs also may result in the routine use of 3D printed forms of oral medication. “Even today, it’s common to individually purchase locally fabricated drugs in the pharmacies. I can envision a future in which a patient brings her/his prescription to the pharmacy and the pharmacist prints a personalized form of oral medicine. Of course we have to wait for the dissemination of 3D printers and software for this to happen,” comments Dr. Szilárd Pál, the Director of the Institute of Pharmaceutical Technology and Biopharmacy.

The personalized 3D medicine printing may soon provide a solution in the case of the commonly referred to, ‘orphan drugs’. These forms of medicine were developed to treat considerably rare diseases, however, since there are comparatively individuals suffering from rare disease, major corporations generally refrain from fulfilling mass production of these forms of medication. Interestingly a host of rare diseases remain a threat to humankind, which implies many patients do not have easy access to this category of medication. In many of cases, patients suffering from a rare disease originate among the most vulnerable portions of the general population, for example, children struggling with rare metabolism disorders.

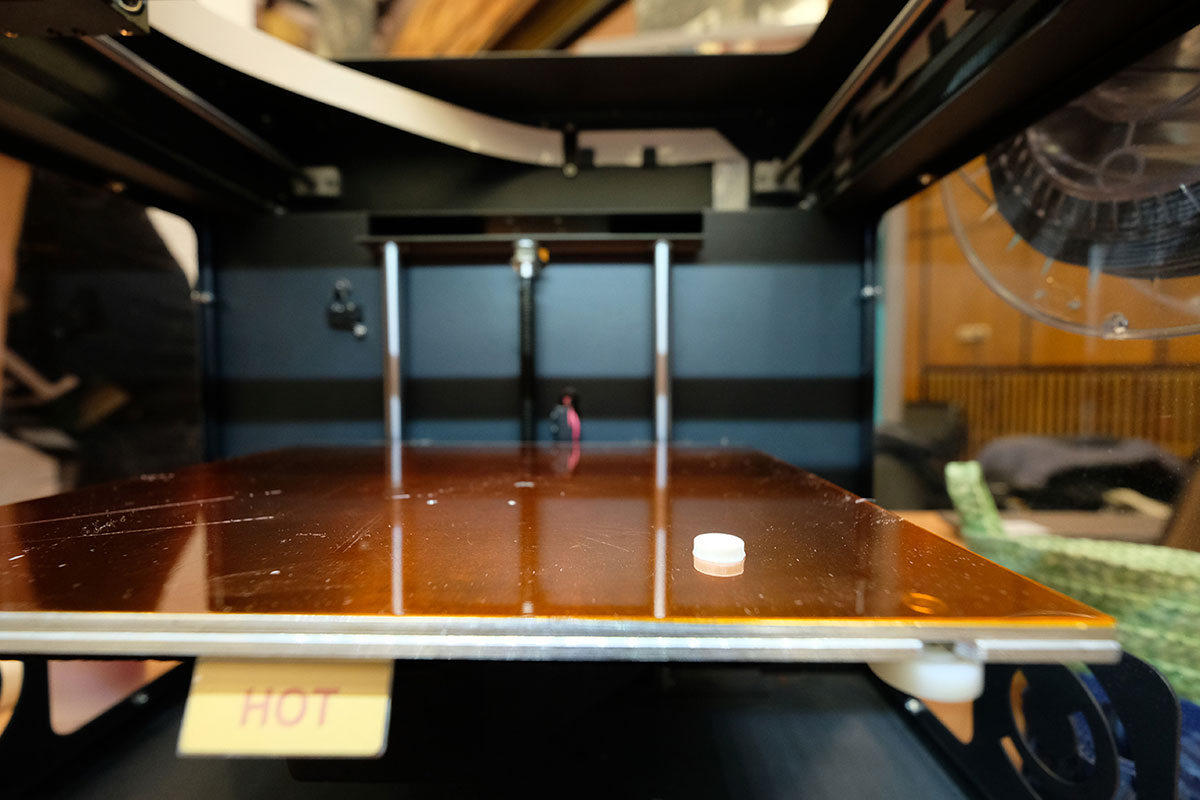

Obviously, a proportionately immense quantity of research and product testing faces the research team and, distinctly, the University’s 3D Print Technology Center plays an essential role regarding this herculean effort. “During our first round of examinations, the team successfully printed poly lacton acid-based composites, which will be implemented in consideration of the variety of patterns, fulfilling percentages and printing orientations. We are now in the process of planning the preclinical phase. Additionally, we are planning to acquire specialized equipment generally associated with manufacturing medicine, in cooperation with the Institute,” proudly explains Dr. Péter Maróti, the newly appointed, 3D Print Technology Center’s Innovation and Development Manager.

Following completion of the preclinical phase, the 3D Print Technology Center moves forward into the realm of animal and clinical trials. In regards to humans, the researchers have targeted an important patient group in mind. The researchers of the Faculty of Pharmacy and in association with the University’s 3D Print Technology Center plan to create an ‘artisan medicine’ ideally suitable in the effective treatment of sudden and critical rising blood pressure.