References

Foundation Stone for UPMS

Preparation of a SLS-model for the foundation stone of the new educational block of the University of Pécs Medical School, as a representative contribution produced in a small series.

Pécs Zoo project

Collaboration with the Pécs Zoo Nonprofit Ltd. for the 3D printing of exotic animal skeletons (e.g. chameleons, turtles) or parts of animals (e.g. zebra skull, tiger skull) using SLS and FDM technologies for educational and display purposes.

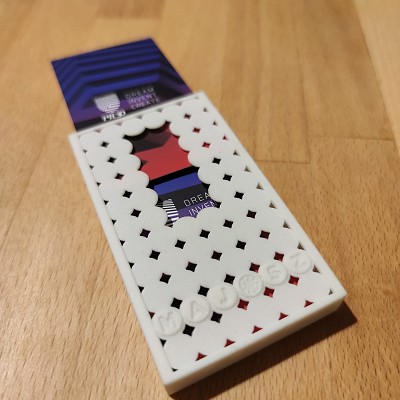

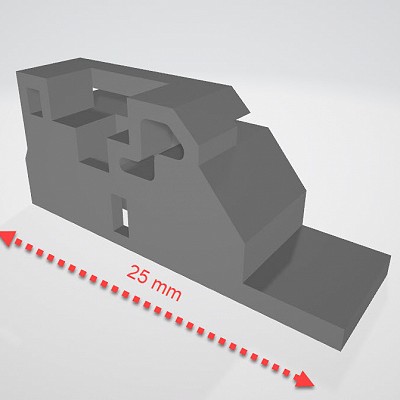

Business card holder

Business card holder for the 25th anniversary conference of the Association of Hungarian Automotive Component Manufacturers (MAJOSZ), produced in a small series with SLS technology.

Polyjet transparent head

Human head in 1:4 ratio with annotated nasal cavities, oral cavities and sinuses, made as an educational aid. The head is completely transparent, but the different organs are separated by different colours. A 3D scanned version of the customer’s own face was reproduced.

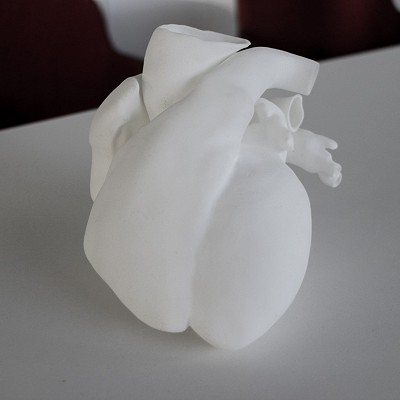

Reproduction of human organs using 3D printing

Reproduction of various human organs, mainly using SLS and SLA technologies, for surgical preparation or as an educational aid that facilitate preparing medical teams. The 3D models produced from medical imaging scans after segmentation result in tangible plastic models that, when held in the hand, clearly show the vast majority of changes and lesions.

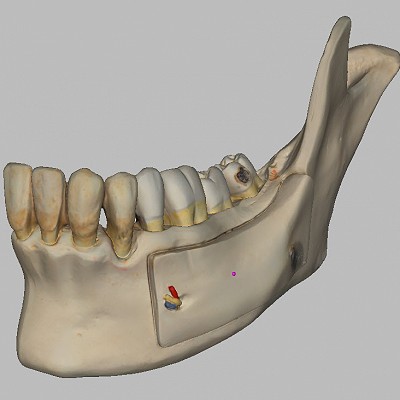

Dental Kit

Modular educational training set for dental students with freely variable content, commissioned by the Department of Dentistry and Oral Surgery of the University of Pécs, using SLA and SLS technologies and silicone casting.

Solar Decathlon 2019

SLS and FDM design and printing of the joint entry piece submitted by the University of Pécs, University of Miskolc and the Saad Dahlab Univerity of Blida, Algeria (USDB) for a university innovative building competition, which won 2nd place in the architectural category and 3rd place in the energy efficiency category.

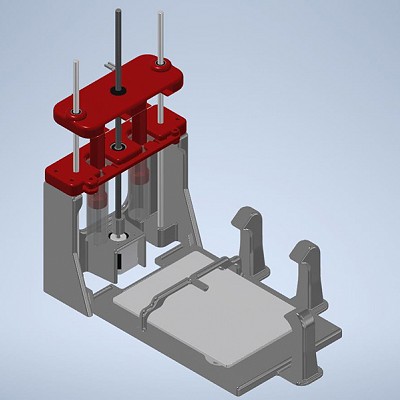

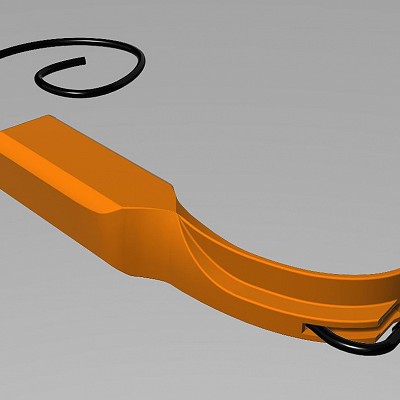

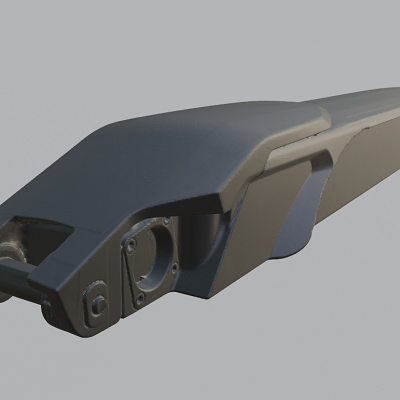

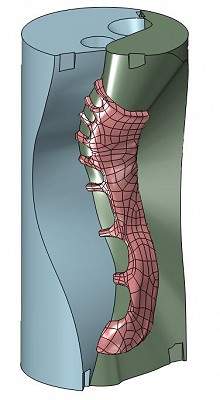

Your Anastomosis

Partnership with ME3D - Graft Ltd. for the prototype development of the “YourAnastomosis” simulator and instruments product line. The product is a “vessel filling” device for the preparation of FEA analysis, capable of injecting polyurethane or resin into the inner lumen of simulated vessel sections, ensuring the subsequent use of an accurate impression. The UP-3D Centre also provided design services for the development of this product.

Phoenix project - Gelányi Innovations Ltd.

3D printing, scanning, material testing and design for the development and construction of an orthosis to replace missing hand functions in patients with spastic paralysis of the hand, as part of the Phoenix project of Gelányi Innovations Ltd.

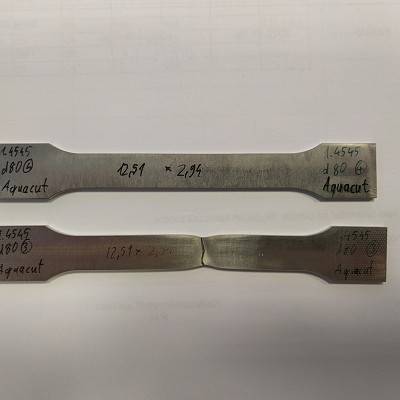

Aquacut Ltd.

Fracture testing for Aquacut Ltd. to control the quality of raw materials.

Hauni Hungaria

Shore hardness measurement and testing for Hauni Hungaria for product quality control.

Bleeding Skin

The Bleeding Skin is a medical simulation device for the University of Pécs Medi Skills Lab, tested for small-scale production using two-component silicone and artificial blood, which allows students to practice incisions on skin simulated with lifelike material properties that can bleed naturally and evenly.

Surgical suture pad

We regularly produce surgical suture pads using two-component silicone and fat tissue mimicking fillers. Students first use these to practice using surgical suture thread and various stitching techniques.

Medical simulation bones

We can produce educational or custom bone simulations in small batches. The bones are made with a solid polyurethane surface and a rigid foam polyurethane interior, with a hollow core if required. We currently have moulds for bones of the upper arm, forearm, thigh and lower leg. On request, we can make silicone moulds based on segmented 3D models from physical samples, 3D scans or medical image samples, which can be used to mould 20-40 products.

VR Campus – accessible from UPMS & UPFEIT

During the virtual campus project, the UP-3D Centre engineers modelled the University of Pécs Campus and made different university facilities accessible. The entire Medical School and the Faculty of Engineering and Information Technology campus can be visited in VR with Oculus Rift and demonstration classes are also available for visitors. The Aula of UPMS can be accessed in browsers, from desktops and in VR environments, and all exhibitions are regularly updated and can be viewed online.

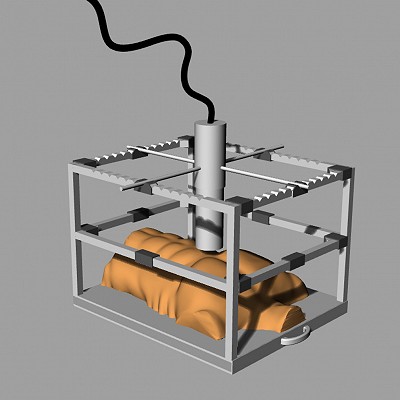

Scintigraphic model for UP MS Department of Biophysics

For this project, the aim was to create an artificial chest mounted on a box with a drawer. Small indentations and sockets created on the pull-out drawer plate are used for the random placement of radioactive preparations. A 3D-printed frame is placed over the chest, on which the detector can be placed in certain ‘slots’. Students use the equipment to measure the exact location of the preparations “invisibly”, using only the detector. The results are verified by means of the ‘slot detectors’, which are marked with numbers and letters.

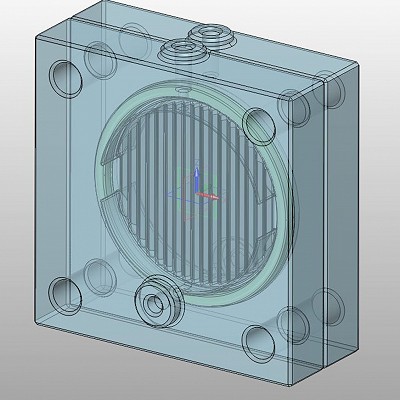

3D printed diffusion cells for UP Faculty of Pharmacy

The principle of operation of a diffusion cell is that two flowing fluid masses are only separated by only a thin membrane. Depending on the properties of the membrane and the fluids, selective diffusion occurs between the two fluid spaces, achieving the required particle mixing. The UP-3D Centre designed and manufactured such devices in-house for the Faculty of Pharmacy based on the study of existing similar devices.

Various CAD-models

Experts at UP-3D Centre have created 3D models of a variety of medical technology and healthcare simulation devices using CAD processes. The Centre’s experienced engineering team is ready to provide accurate and efficient assistance at any stage of product design.

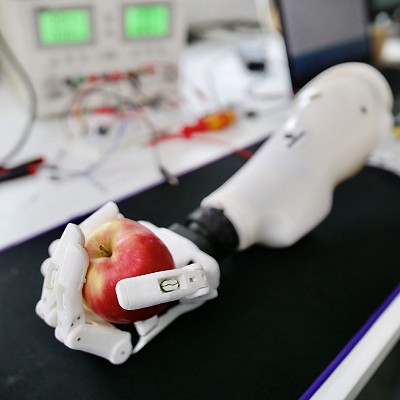

Human Arm Prosthesis Development

Prolimb Ltd. was established as a spin-off company of the University of Pécs following a venture capital investment. Its objective is to develop a highly functional, 3D printable and myoelectrically-controlled upper limb prosthesis.

Cooling Plate

We were commissioned to design a medical device, which was achieved by designing a closed cooling plate with the thinnest possible wall thickness, using the most extensive pipe system able to circulate cooling fluid inside, and it was produced with an SLA printer. Transparency was also a criterion to allow observation of the coolant flow, which was achieved with FormLabs’ transparent resin. The cooling plates function as accessories to a device for carrying out various biological experiments, so the design had to take into account the basic needs of the device for efficient operation.

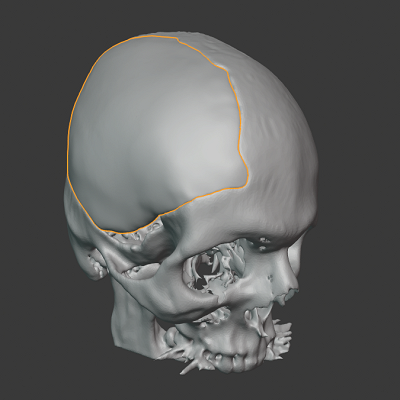

Skull moulds

In surgical design, SLA technology is used to print the moulds required to make the skull implant from which the mould is made with precision at tenths of a millimetre.

MiniMe

Nowadays, our own 3D-printed images have become trendy gifts. Couples, parents and grandparents are gifting each other with their own colourful 3D printed miniature models, called MiniMe. Featuring both handheld scanners that can perfectly digitise the human body and a PolyJet printer that prints in rainbow colours, the UP-3D Centre also allows customers to immortalise themselves for eternity in the form of small or large 3D printed sculptures.

Logos for fashion items

Brand logos printed on fashion items using Polyjet technology demonstrate the versatility of the machine and this technology.

3D scanning of human body parts and organs

3D scanning of human jaws, teeth, ear bones and other human organs for medical visualisation.

3D scanning of a bicycle battery

Scanning of an electric bicycle battery for the purpose of reproduction.

Reverse engineering reproduction of a light switch

Reproduction of a light switch by 3D scanning for the purpose of testing reverse engineering.

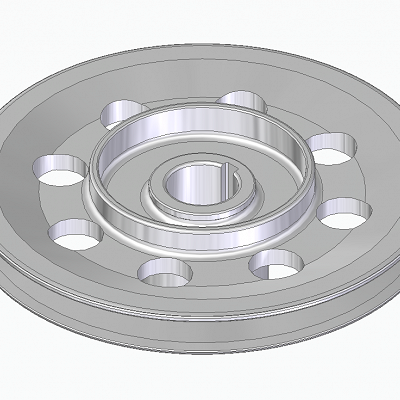

3D scanning of car parts

3D scanning of various car parts (drive belt pulleys, brake drums) for reverse engineering.

3D scanning of medical prosthesis

3D scanning of medical prosthesis for design or reverse engineering.

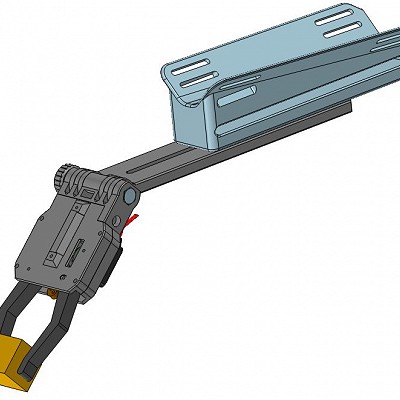

Design and manufacture of prosthetic devices

The UP-3D Centre has designed and manufactured a myoelectric test prosthesis for the Institute of Behavioural Sciences. The project involved the development of a forearm-mounted gripping device to measure the cognitive capacity of prosthetic use in healthy people. Electrical signals from the forearm muscles control the device, which is driven by a servo motor and has custom-made 3D printed parts.

Pet goggle design

The UP-3D Centre has designed pet goggles for experiments at the Institute of Physiology. The glasses, printed in flexible material using SLA technology, fit the actual head shape well and allow for easy replacement of lenses.

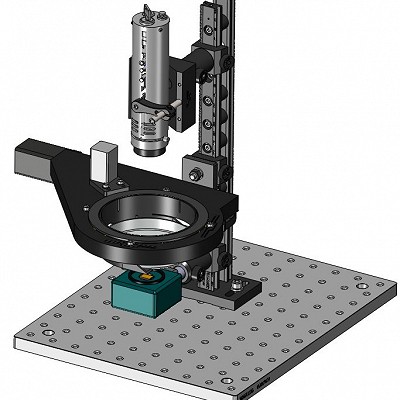

Lensless microscope design

The UP-3D Centre has designed, printed and assembled a lensless microscope for the Institute of Microbiology. The microscope was assembled from commercial components and 3D printed parts, and unlike conventional light microscopes it does not include an imaging lens system. The holographic image of the laser beam passing through the sample under examination is detected using CMOS technology and can be viewed digitally magnified.

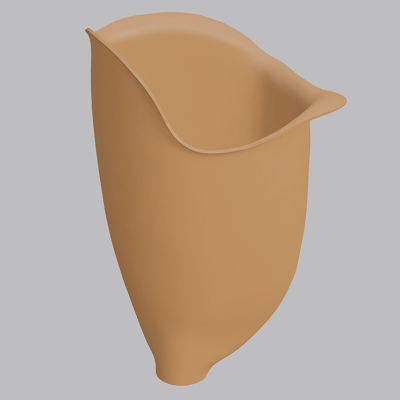

Gingival dental mould design

The UP-3D Centre has designed and printed gingival moulds for the Dental Clinic. A printed mould for the casting of silicone gum detail was designed for illustrative purposes for an educational and training toolkit. This organic mould is a good example of the versatile application of our design and 3D printing technologies.

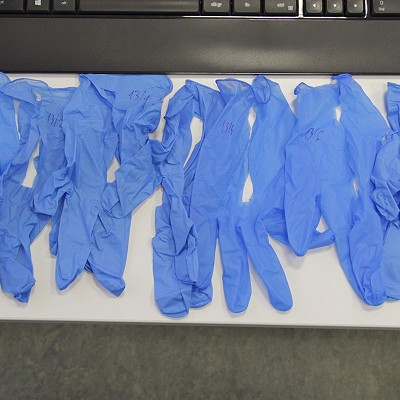

Tensile testing of medical gloves

The UP-3D Centre has performed tensile testing of rubber gloves for medical use according to EN 455-2:2015 protocol. The customer provided 12 boxes of gloves from the same manufacturer in different colours and sizes. The gloves were non-sterile, latex-free, ambidextrous, disposable and powder-free. The test pieces were cut out of the gloves using a punching template with a geometry as described in the standard. The purpose of the material test was to examine the tensile strength and elongation parameters of the glove sets.

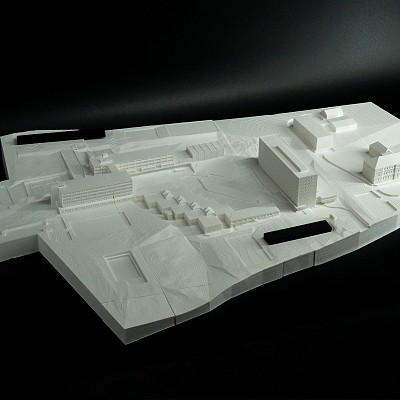

UP-FEIT campus model

Faculty of Engineering and Information Technology, printed with FDM technology at a scale of 1:800.

- Modelled by Péter Paári